|

Is Your Data Ready for AI Implementations? |

At ThirdEye Data, we develop AI solutions for the manufacturing industry to shift their operation from reactive to proactive. Like any business investment seeking higher ROI, manufacturers investing in AI programs are no different. Therefore, we focus on AI applications directly impacting the company’s revenue.

Our recently developed AI solutions are fundamentally reshaping manufacturing operations by improving overall equipment efficiency or OEE, saving costs with predictive maintenance or PdM of the machines, and enhancing product quality in real time.

Let us discuss our experience, solutions, and commitment to AI implementation in manufacturing operations.

Five years ago, when we first developed our AI solution for a manufacturing company, integrating AI solutions was seen as a complex, costly endeavor only feasible for large manufacturers with big budgets.

That makes us think that AI must be accessible to all sizes of manufacturers, as it has a huge prospect of generating revenue. We are committed to democratizing AI for all.

ThirdEye has spent over ten years delivering AI-powered solutions and worked on more than 20 use cases for the manufacturing industries. From the AI use cases we have worked on, we have found that the primary business needs in the manufacturing sector center around efficiency, quality, cost management, and adaptability. Here are some of the primary AI use cases in the manufacturing industry:

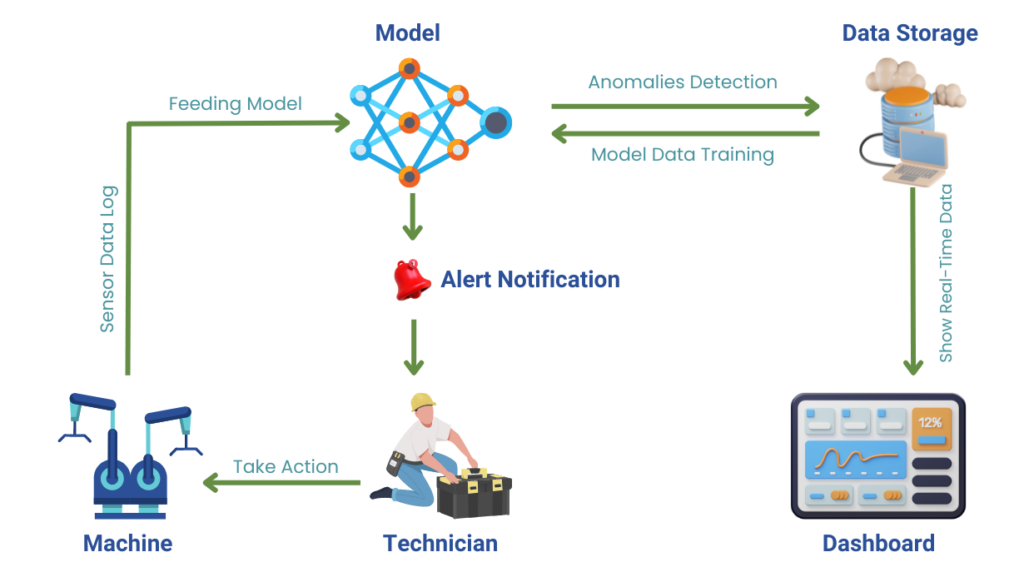

One of the biggest applications of industrial artificial intelligence is in predicting equipment failures before they occur by analyzing and detecting anomalies in sensor data, historical maintenance records, and operation floors data.

Manufacturers prioritize minimizing unplanned downtime that disrupts production schedules and reducing the financial burden of unexpected machine breakdowns and lengthy repair times by deploying factory AI solutions. To achieve this business goal, we develop AI-powered predictive maintenance (PdM) solutions that analyze the processed data and generate results in real time. You can find more details on PdM in our solutions section below.

Manufacturers need to cut down on material waste and rework costs, which directly affect profitability. Therefore, they are taking two different approaches – Reactive and Proactive. And, the AI solutions are getting deployed in assembly lines, welding, painting, and packaging processes.

In a reactive approach to maintaining product quality and reducing waste, they prefer to leverage computer vision and deep learning technologies to build AI-driven quality control systems. These systems automatically inspect products for defects by analyzing image data from machine-mounted cameras, historical product data, and real-time operational data, ensuring they meet precise specifications. This shift from manual inspections to AI-driven processes enhances accuracy, speed, and consistency in detecting defects on production lines.

With a proactive approach, manufacturers focus on ensuring that measurement systems remain precise and calibrated throughout the production process in real-time. By predicting potential measurement errors early, the integrated system ensures that products are manufactured with tighter tolerances, reducing the likelihood of producing defective parts with such as dimensional inaccuracies or surface irregularities, because they are based on reliable data. To achieve this goal, manufacturers need predictive metrology systems that identify a potential deviation in measurements (e.g., due to tool wear), it can trigger the quality control system to inspect products more rigorously or make real-time adjustments to the machine settings, preventing quality issues.

Supply chain disruptions can be catastrophic for smaller manufacturers. Manufacturers look for an AI-powered system that can forecast demands by analyzing market data, provide real-time analysis reports to enhance inventory management, and offer alternative routes for faster and smoother transition by analyzing GPS data. The business goals are to reduce stock-outs and cut inventory holding costs.

AI-powered supply chain analytics platform empowers manufacturers with agility and flexibility in their operations. The AI models analyze supply chain data like information on material flow, inventory levels, market demands, and shipment status in real time and recommend solutions.

Keeping the business goals in mind, we develop customized AI solutions for the manufacturing industry, which are realistic, results-driven, and impact directly on ROI. Our primary AI applications include:

We leverage machine learning, artificial intelligence, computer vision, and IoT technologies to analyze large datasets, identify patterns, and make real-time decisions. Our AI solutions are driving significant improvements across manufacturing operations.

Let us explore the solutions in detail.

Predictive maintenance also referred to as PdM is the use of AI and machine learning algorithms to detect anomalies in sensor data and to predict when equipment is likely to fail or require maintenance, reducing unplanned downtime and optimizing maintenance schedules. PdM shifts maintenance strategies from reactive, that is fixing machines after breakdowns, to proactive like preventing breakdowns.

We use computer vision and machine learning to build AI-powered quality control systems that automatically inspect products for defects, ensuring they meet precise specifications. This shift from manual inspections to AI-driven processes enhances accuracy, speed, and consistency in detecting defects on production lines.

Our AI-powered supply chain optimization solutions help manufacturers with demand forecasting, inventory management, and smart logistics approaches by analyzing vast amounts of data from across the supply chain.

By identifying patterns and trends, the system enables manufacturers to streamline processes, minimize delays, and optimize resource allocation.

Our predictive metrology system is a popular application of AI and machine learning to monitor and predict the calibration needs and accuracy of measurement tools and systems in manufacturing. It combines the principles of predictive maintenance, process control, and metrology or the science of measurement to anticipate measurement deviations and ensure consistent product quality. Predictive Metrology and AI-powered Quality Control are closely integrated, as both aim to enhance product quality and consistency throughout the manufacturing process.

Predictive Metrology is focused on ensuring that measurement systems remain accurate throughout the production process, while AI-powered Quality Control is focused on detecting defects in real-time.